RPM and Technische Universität Dresden has developed a new testing procedure for the identification and quantification of minerals in paper, board and (recycled) pulp. The knowledge of both, the exact amount and type of fillers in a paper, a board or a recycled pulp is important in order to

- control major quality parameters,

- improve the efficiency of additives,

- improve economics,

- optimize furnishes,

- optimize the use of new minerals,

- introduce new process control strategies.

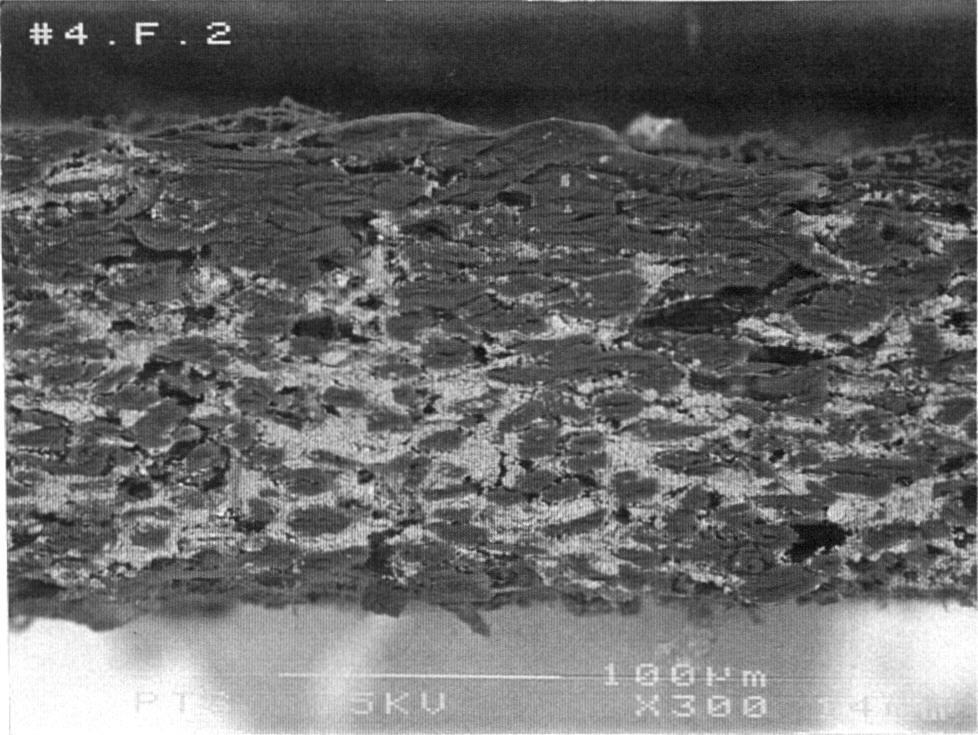

It’s well know, that fillers strongly influence a lot of major properties of the final paper, e.g. gloss, opacity, brightness, porosity and ink absorption, bulk, viscosity, strength, drying rate and formation. But paper for recycling (waste paper) can – as a function of origin and collection system – contain any conceivable components and additives in unknown quantities, like e.g. fillers, pigments, sizing agents, starch, colours and dyes. Their concentration can change along the whole process chain in a difficult to predict way due to retention, agglomeration and deposits, accumulation, cleaning and separating.

The goals of our development are important properties of the analysis of minerals in paper, board and pulp like

- be non-destructive,

- be promt & in-line,

- not require demanding sample preparation,

- be easy to handle

- allow for a real elemental analysis,

- potentially support on-line measurements.

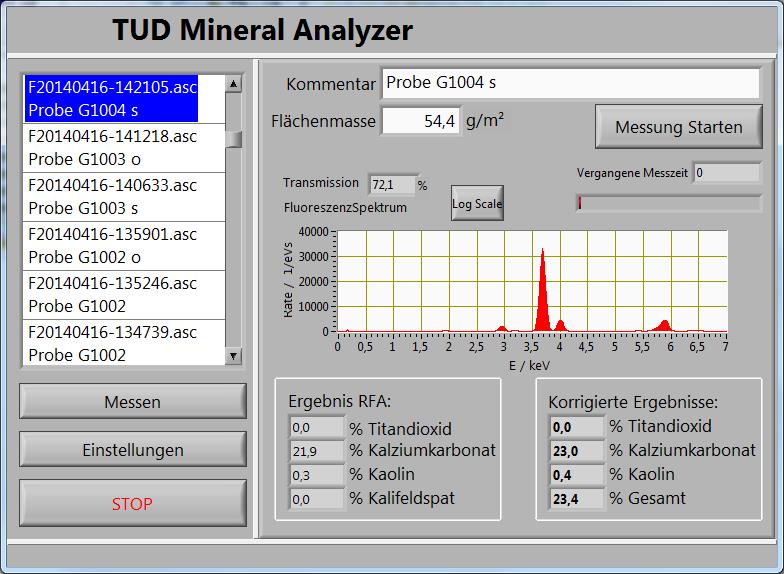

It is also important to have independence from the chemical bonds of the fillers and the moisture of the paper and other conditions. So we use X-ray fluorescence analysis (RFA) in combination with absorption measurement with a Fe55-source and ionization chamber.

We are able to find all elements form Al to Ba. Based on the signals of the RFA and our knowledge of paper components we can find out the filler and calculate the concentration with a accuracy less than 1%.

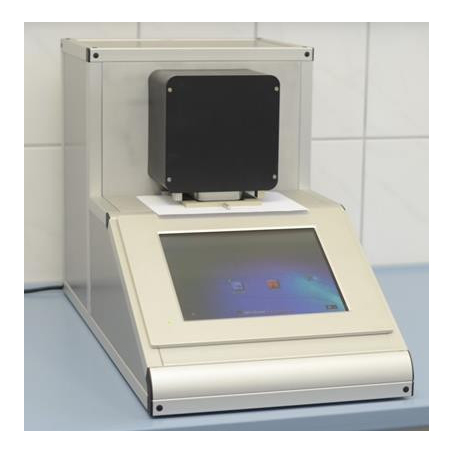

The result of our development is a measuring instrument for laborites which is ready to use. You can also use it near by the paper making machine. It is based on modify hardware components and a own software with our algorithms, which we find out.

In the meantime it has already been successfully tested on a pilot paper machine as well as on a full size production unit.

Please contact us to test your own paper and our brand new instrument itself.